INFORMATION

Composite Cord Strapping: The Ideal Solution for Heavy-Duty Applications

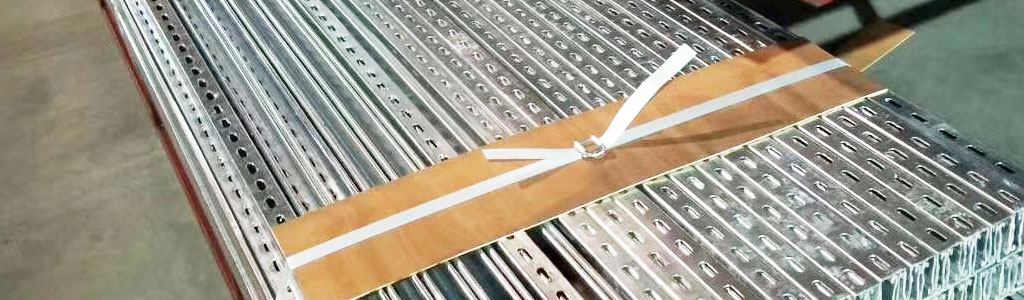

Composite Cord Strapping has revolutionized the packaging and transportation industries with its innovative design and superior performance. Manufactured using the highest quality materials, it offers unparalleled strength, flexibility, and durability. This article explores the unique features, advantages, and applications of **Composite Cord Strapping**.

What is Composite Cord Strapping?

Composite Cord Strapping is a co-extruded polyester strapping made from high-tenacity polyester fibers encased in a polypropylene coating. The design consists of parallel polyester threads, providing exceptional tensile strength and shock resistance. This advanced strapping is one of the latest developments in non-metallic shipping technology and has become a preferred choice for industries requiring heavy-duty packaging.

Key Features

1. Durability and Strength

- Composite Cord Strapping offers excellent tensile strength, making it suitable for securing heavy loads like transformers, steel, and machinery.

- Its "synthetic steel" moniker underscores its ability to replace traditional steel straps while maintaining reliability.

2. Resistance to Environmental Factors

- Unlike steel strapping, Composite Cord Strapping does not rust, ensuring long-lasting performance in humid or wet conditions.

- It resists UV radiation and temperature fluctuations, making it ideal for long-term outdoor storage.

3. Flexibility and Light Weight

- The flexible nature of the strap allows it to conform to various load shapes without losing tension.

- Its lightweight design reduces worker fatigue and simplifies handling and application.

4. Shock Absorption

- Composite Cord Strapping provides excellent shock resistance, making it suitable for long-distance transportation over uneven terrain.

5. Recyclable and Eco-Friendly

- As an environmentally friendly alternative to steel, it is fully recyclable and contributes to sustainable packaging practices.

Advantages of Composite Cord Strapping

1. Safety

- The absence of sharp edges reduces the risk of injury during handling and application, ensuring worker safety.

2. Cost-Effectiveness

- Lower material and shipping costs compared to steel strapping.

- Its reusability further enhances cost savings.

3. Ease of Use

- Requires minimal tools for application and is compatible with manual or pneumatic tensioning systems.

4. Damage Prevention

- The non-abrasive surface prevents scratches or dents on the goods, protecting their integrity during transport.

Applications

Thanks to its exceptional properties, Composite Cord Strapping is widely used across various industries:

1. Heavy Machinery and Equipment

- Securely straps transformers, industrial machines, and other heavy equipment during transit.

2. Steel and Metal Industry

- Ideal for bundling steel coils, pipes, and sheets, offering a non-corrosive alternative to steel straps.

3. Logistics and Shipping

- Provides reliable load stability for long-distance and international shipments.

4. Construction Materials

- Effectively binds materials like timber, bricks, and tiles for safe transport.

5. Automotive Industry

- Used to secure auto parts and components, ensuring safe delivery without surface damage.

Why Choose Composite Cord Strapping?

Composite Cord Strapping stands out as an advanced, practical, and eco-conscious alternative to traditional strapping methods. It combines the best qualities of polyester and polypropylene materials, ensuring reliable performance even in demanding environments. Whether you're in the logistics, construction, or manufacturing sector, this versatile strapping solution meets the highest standards of safety, durability, and sustainability.

By adopting Composite Cord Strapping, businesses can reduce costs, enhance operational efficiency, and contribute to environmental preservation, making it a win-win solution for modern packaging needs.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved