INFORMATION

Everything You Need to Know About Heavy-Duty Lashing Straps

In the world of transportation, logistics, and cargo handling, safety and stability are paramount. Whether it’s securing large machinery on a flatbed truck or bundling construction materials for shipping, the right equipment can make all the difference. One such essential tool in this process is the heavy-duty lashing strap. Though often overlooked, lashing straps play a critical role in ensuring cargo stays in place during transit, protecting both goods and people.

But what exactly are heavy-duty lashing straps? How do they work, and why are they so widely used across different industries? In this article, we’ll explore everything you need to know about these robust tools, from their structure and materials to their applications, benefits, and best practices.

What Are Heavy-Duty Lashing Straps?

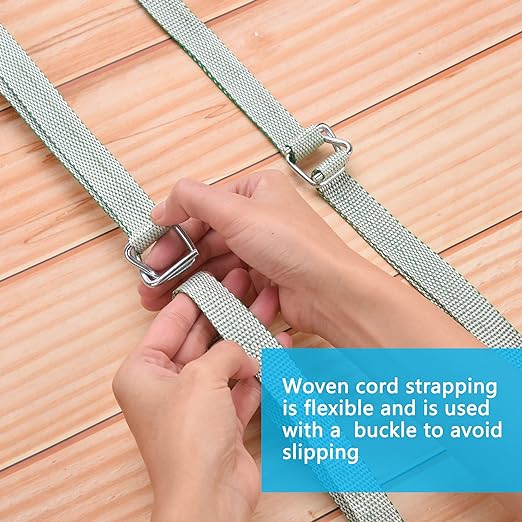

Heavy-duty lashing straps, also known as cord lashing straps or tie-down straps, are flat webbing straps designed to secure heavy cargo during transportation. These straps are manufactured to handle high tension and extreme loads, making them ideal for industrial applications, overland shipping, and container fastening. Unlike ropes or chains, lashing straps offer a combination of strength, flexibility, and ease of use, which is why they’ve become the go-to solution for many logistics operations.

Lashing straps typically consist of two main parts: a length of strong webbing (usually made from high-tensile polyester) and a tensioning device, such as a ratchet or buckle. The webbing is threaded through the tensioner, tightened over or around the cargo, and locked in place, preventing movement during transport.

Key Features of Heavy-Duty Lashing Straps

Several characteristics distinguish heavy-duty lashing straps from standard tie-down equipment. These include:

- **High Load Capacity**: Heavy-duty straps are engineered to withstand significant force, with break strengths ranging from 1,000 kg to over 5,000 kg depending on the design. This allows them to secure extremely heavy and bulky items safely.

- **Durability**: The materials used in these straps, particularly industrial polyester fibers, are resistant to abrasion, moisture, UV rays, and many chemicals. This durability ensures long-term use in tough environments.

- **Flexibility**: Unlike rigid securing systems, lashing straps can conform to the shape of the load. This reduces pressure points and prevents damage to the cargo.

- **Portability**: These straps are relatively lightweight and easy to store, making them convenient for use in a wide range of situations.

Common Applications

Heavy-duty lashing straps are widely used in industries such as construction, freight forwarding, marine shipping, agriculture, and warehousing. Some common applications include:

- Securing cargo inside containers or on flatbed trucks

- Fastening construction equipment or building materials

- Holding down large crates or pallets

- Bundling pipes, steel rods, or wooden beams

- Stabilizing machinery or industrial tools during relocation

In each of these cases, the primary goal is to prevent shifting, slipping, or tipping of the load, especially under dynamic conditions such as vibration, acceleration, or sudden braking.

Benefits of Using Heavy-Duty Lashing Straps

When compared to other securing methods like metal chains, plastic straps, or ropes, heavy-duty lashing straps offer several clear advantages:

- **Safety**: Properly tensioned straps prevent cargo from moving, reducing the risk of accidents or injuries caused by falling or shifting items.

- **Efficiency**: Fast to install and remove, they save time during loading and unloading.

- **Cargo Protection**: The soft yet strong webbing material is gentle on the cargo, avoiding scratches or dents that harder materials like chains might cause.

- **Cost-Effectiveness**: Reusable and long-lasting, lashing straps offer a strong return on investment.

Tips for Proper Usage

Using heavy-duty lashing straps properly is crucial to maximizing their effectiveness and lifespan. Here are some practical tips:

- **Inspect Before Use**: Always check the straps for fraying, cuts, or wear. Damaged straps should be replaced immediately.

- **Use the Right Strap for the Job**: Choose a strap with the appropriate length and working load limit (WLL) for your cargo. Never exceed the rated capacity.

- **Ensure Secure Anchor Points**: Attach the ends of the strap to strong, stable anchor points to ensure the load stays in place.

- **Avoid Twisting**: Straps should be laid flat and not twisted during use, as twisting can reduce their strength and cause uneven pressure.

- **Store Properly**: After use, keep your straps clean and dry. Store them away from direct sunlight or harsh chemicals to prolong their life.

Conclusion

Heavy-duty lashing straps are an indispensable part of modern cargo management. Their strength, reliability, and versatility make them a smart choice for professionals across numerous sectors. Whether you're shipping machinery overseas or transporting lumber to a construction site, using the right lashing strap can mean the difference between a successful delivery and a costly accident.

By understanding how these tools work and adhering to proper usage practices, businesses can improve their logistics efficiency while protecting their goods and personnel. As the global demand for safer, more sustainable transport solutions continues to grow, heavy-duty lashing straps will remain a key component in securing the world’s cargo.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved