INFORMATION

Lashing Strap: The Ultimate Guide to Secure Cargo Transportation

Introduction

In the world of logistics and transportation, securing cargo properly is crucial to ensure safety, prevent damage, and comply with regulations. One of the most effective tools for this purpose is the **lashing strap**. Whether you are transporting goods by truck, ship, train, or air, lashing straps provide a strong, flexible, and cost-effective solution for securing loads. This comprehensive guide will explain everything you need to know about lashing straps, including their types, benefits, applications, and best practices for safe and efficient cargo transportation.

What is a Lashing Strap?

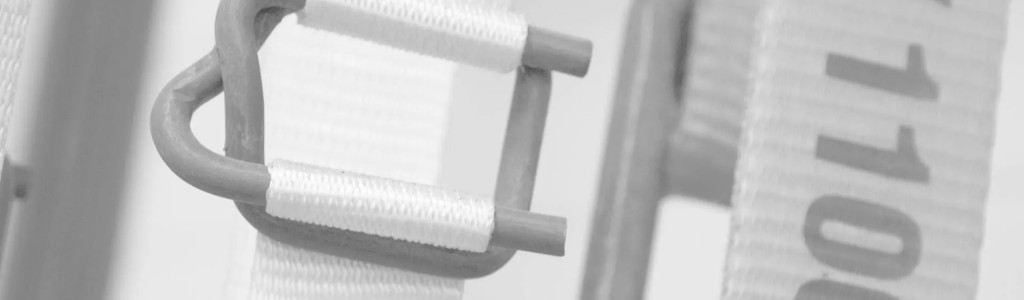

A lashing strap, also known as a **woven cord strapping** , is a strong, durable strap designed to secure cargo during transportation. These straps are typically made from **polyester**, **nylon**, or **polypropylene**, offering high tensile strength and resistance to abrasion, moisture, and UV exposure. Lashing straps are used in various industries, including logistics, shipping, construction, and warehousing, to keep cargo stable and prevent shifting during transit.

Types of Lashing Straps

Lashing straps come in different types, each designed for specific applications. The most common types include:

1. **Ratchet Lashing Straps**

- Feature a ratchet mechanism that allows for precise tightening and secure fastening.

- Ideal for securing heavy loads in trucks, trailers, and shipping containers.

2. **Heavy-Duty Webbing Straps**

- Made from high-strength polyester webbing, offering extreme durability.

- Used for securing oversized and heavy cargo in transportation and construction.

Benefits of Using Lashing Straps

Using lashing straps for cargo securing provides multiple advantages:

**High Strength and Durability**: Made from tough materials, lashing straps can withstand extreme forces and harsh weather conditions.

**Adjustability and Flexibility**: Unlike chains or ropes, lashing straps can be adjusted easily to fit different cargo sizes and shapes.

**Lightweight and Easy to Handle**: Lashing straps are much lighter than metal chains, making them easier to use and transport.

**Cost-Effective Solution**: Compared to other securing methods, lashing straps offer an affordable and reusable option.

**Enhanced Safety**: Properly used lashing straps prevent cargo movement, reducing the risk of accidents, damage, and injuries.

How to Use Lashing Straps Properly

To ensure maximum security and effectiveness, follow these steps when using lashing straps:

1. **Select the Right Strap for Your Load**

Choose a lashing strap with the appropriate **breaking strength (BS)** and **working load limit (WLL)** based on the weight of your cargo. For heavy loads, use **ratchet lashing straps** with a high load capacity.

2. **Inspect the Straps Before Use**

Check for any signs of wear, fraying, cuts, or damage. Damaged straps should be replaced immediately to avoid failure during transportation.

3. **Position the Straps Correctly**

Place the straps over or around the cargo in a way that ensures even weight distribution. If using multiple straps, make sure they are positioned symmetrically for balanced tension.

4. **Secure the Straps Properly**

Use the ratchet, cam buckle, or over-center mechanism to tighten the strap securely. Avoid over-tightening, as it may damage the cargo or the strap itself.

5. **Double-Check the Load Before Moving**

Before starting transportation, perform a final inspection to ensure all straps are properly secured and the cargo is stable.

6. **Recheck During Transit**

If traveling long distances, stop periodically to inspect the straps and re-tighten if necessary. Straps can loosen due to vibrations or load shifts.

Common Applications of Lashing Straps

Lashing straps are widely used across multiple industries, including:

**Truck and Trailer Transport**: Securing pallets, machinery, and bulk goods on flatbed trucks and trailers.

**Shipping and Maritime Industry**: Fastening containers, crates, and cargo in ships and ports.

**Aviation and Air Freight**: Holding cargo securely in place during air transport.

**Construction and Industrial Use**: Securing materials, scaffolding, and heavy equipment.

**Warehouse and Storage**: Keeping goods stable in storage racks and shelves.

Maintenance and Storage Tips

Proper maintenance ensures the longevity and effectiveness of lashing straps. Follow these tips to keep your straps in good condition:

**Clean After Use**: Remove dirt, grease, and moisture from the straps after each use to prevent deterioration.

**Store in a Dry, Cool Place**: Keep straps away from direct sunlight, heat, and moisture to prevent weakening of the material.

**Avoid Twisting and Knots**: Always store straps neatly without twisting or knotting to maintain their strength and flexibility.

**Regular Inspections**: Check straps periodically for wear and tear, and replace them when necessary.

Conclusion

Lashing straps are essential tools for securing cargo in transportation, offering a safe, reliable, and cost-effective solution for preventing load movement and damage. By understanding the different types of lashing straps, their benefits, and proper usage techniques, businesses and individuals can ensure their cargo arrives safely at its destination. Investing in high-quality lashing straps and following best practices will improve transportation efficiency and safety, making cargo handling more secure and hassle-free.

Whether you are a logistics professional, a truck driver, or a warehouse manager, using the right lashing straps is key to ensuring a smooth and accident-free transport experience.

HomeNewsProductsSolutionDisclaimersPrivacyCooperationContact

Copyright © All rights reserved